All barcodes are the same, aren't they? 🤷♂️

Barcodes have long been indispensable in warehouses. They make a significant contribution to data acquisition and help to optimally track items, merchandise and consignments. But not all barcodes are the same. There are major differences in their suitability for different purposes. We explain what these are about.

by Marc Teuber

book1332 words timelapse7 minutes reading time

This is how Items, Merchandise and Consignments can be tracked in the best possible Way 🔗︎

In everyday business, barcodes are to reliably store data allowing effective tracking. They are needed, for example, to provide up-to-date information about warehouse and item inventories and to track their real time status. This helps centralize the management of warehouse and logistics processes, ensures a better overview and thus an optimal process control.

Today, most barcodes used in pratice can be divided into 1D barcodes and 2D barcodes. 1D barcodes consist of black bars and white spaces and can only store information horizontally. On the other hand, 2D barcodes can store data horizontally and vertically at the same time. They are usually made up of dots or rectangles, also called modules. Advantages of 2D barcodes over 1D barcodes are that they have much greater storage capacity and can be read from all directions using scanning devices. As their use may vary widely in day-to-day operations, barcodes are subject to different requirements. These requirements include aspects such as storage capacity and size or ability to read the barcode without error even if there is an impairment. There are differences here that need to be considered depending on the intended use and conditions. The following five barcode types, which play an important role for tracking in industry today, will be looked at in more detail and their properties will be compared in the further course.

Barcode 🔗︎

Barcodes are the typical representatives of the 1D barcode family. They consist of black bars and white spaces. Information is organized and read horizontally from left to right. Barcodes can be read with conventional laser scanners as well as with more modern imagers. They are still widely used today in merchandise and warehouse management. However, their disadvantage is that they can only store relatively little information. Another disadvantage is that they generally need a high contrast in order to be read properly by the barcode scanner.

DataMatrix Code 🔗︎

DataMatrix is part of the 2D code family and has a relatively high data storage density. However, its decisive advantage is its compactness. The barcode can be placed in the smallest space. There are only a few 2D barcodes - such as the dot code - that are even smaller. This makes it well suited for small parts in warehousing and logistics. Another advantage - one that it also shares with other 2D barcodes - is the relatively good readability with a low contrast. The high correction capability is another advantage: the DataMatrix code can still be read under certain circumstances even if about 30 % of the code surface has been damaged. Compared to the QR barcode, it requires an area that is about 20 % smaller to store the same amount of data. A possible disadvantage could be the above-average print quality that is required to ensure that it is still legible even in smaller versions.

QR Code 🔗︎

QR codes are probably among the most familiar 2D barcodes from everyday life. However, they are not only used in marketing and B2C business, but they are also widespread in logistics as well as in warehouse and merchandise management. One of their advantages - as the abbreviation QR (Quick Response) indicates - is their fast readability. Similar to a DataMatrix barcode, a QR barcode also has a high error tolerance, which, depending on the amount of data stored, can be up to 30 %. Another advantage is that its storage capacity - compared to other 2D barcodes - is in the upper range with more than 4,000 alphanumeric characters. Furthermore, due to its popularity, the QR code is supported by many scanning devices and can be read easily by most smartphones and tablets.

One disadvantage of this code, however, is that it only allows a design using rectangular shapes. This limits its usability for small parts or parts with complex surfaces. In practice, however, there are possibilities to engrave QR codes in mini formats on surfaces using space-saving laser technology. In addition to higher costs and more processing effort, this also requires more of the reader.

Dot Code 🔗︎

The dot code is probably completely right to be the most compact code currently enjoying wider recognition in industrial use. A barcode based on the dot code can be flexibly adapted to many surface shapes. This makes it particularly suitable for small parts or parts with complicated surfaces. Also with the dot code - as with the DataMatrix code - print quality plays a greater role. On smaller surfaces, the print must have sufficient contrast to be easily scannable by the readers. Of course, this also places higher demands on the barcode printers used.

Jab Code 🔗︎

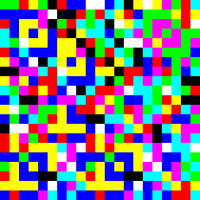

The special feature of the JAB code is its ability to also use colours for data storage in addition to horizontally and vertically arranged characters. With the eight colours that are available, the storage capacity can be increased to about three times that of the usual 2D barcodes. Another advantage is that the barcode is not limited to rectangular shapes. It can also take on other shapes, such as a u-shape. This makes for diverse and flexible application options. However, its advantages could become disadvantages in some circumstances: In harsh environments, the paint can be damaged more quickly. Furthermore, it can fade over time due to UV light. This places correspondingly high demands on countermeasures such as print quality or light and abrasion protection.

Overview of all relevant Bar Codes 🔗︎

| Barcode | DataMatrix Code | QR Code | Dot Code | JAB Code | |

|---|---|---|---|---|---|

| Barcode Type | 1D | 2D | 2D | 2D | 2D coloured |

| Error Tolerance | low | high fault tolerance up to approx. 30 %. | fault tolerance up to approx. 30 %. | high fault tolerance up to approx. 25 %. | high fault tolerance in 11 Levels. Level selectable depending on the amount of data stored. |

| Robustness | high contrast requirements (minimum value up to 80 %) | possibly less legible due to small size (Higher print resolution required) | low contrast requirements (from approx. 15 %) | possibly less legible due to small size (higher print resolution required) | colour may fade over time due to UV light |

| Suitable for Small Parts | less suitable | well suited (very compact). The same amount of data can be stored on an area 20% smaller than the QR code. | comparatively large surface. little scope for design, as only rectangular shapes are possible. Mini QR codes can be engraved with laser technology. Mini QR codes can be engraved with laser technology. | very well suited due to small size. flexibly adaptable to different surfaces. | flexible attachment, as not being limited to rectangular or square shapes. Can take on different shapes, such as a u-shape. |

| Storage Capacity | very low approx. 25 characters | average up to approx. 2300 alphanumeric characters | above average up to 4000 alphanumeric characters | average | very high about three times the data density compared to black and white 2D codes |

| Readability | can only be read from left to right | readable from different directions | readable from different directions | readable from different directions | readable from different directions |

| Other | widely used in the production sector due to many years of familiarity and simple handling. | supported by many barcode readers. Very compact. high resolution label printer needed (for small barcodes). | engraved barcodes need high quality and accurate readers. supported by many barcode scanners. high recognition value as being familiar from everyday life. | not yet supported by many reader apps. E.g. Snowflake, Dot A high-resolution label printer needed (for small barcodes). | high print quality required to display colours with high contrast |

Summary 🔗︎

Different barcode types have both strengths and weaknesses and their use should be individually tailored to the tasks to be solved. However, the use of barcodes in today’s warehouse management and logistics must overcome some general challenges. In addition to sufficient storage capacity, these include in particular good readability, which should also be given under difficult conditions. This includes adequate print quality and high error tolerance. Furthermore, due to the trend towards miniaturization, the compactness of barcodes used is gaining importance.

Selection Criteria to be considered

On the one hand, customers expect faster deliveries. On the other hand, the diversity of variants and miniaturization pose great challenges for logistics and warehouse management. Mobile data capture plays an important role in this context. Against this background, we are discussing which criteria are to be considered when choosing a barcode scanner.

Smartphones vs. professional Mobile Device Scanners

In addition to professional MDE solutions, smartphones are increasingly being used as barcode scanners today. For less demanding tasks, they can play to their strengths. However, as requirements increase, their advantages increasingly fade - until they have to pass the baton to professional MDE devices. In the end, it’s careful consideration what counts.